East West provides more than global manufacturing. We can help whether you already have a project being manufactured elsewhere and are looking for a new supplier, or you are looking to scale production. Managing projects from design to delivery, we take a concept, turn it into a design, manufacture the product to world-class standards and handle the entire logistics process of delivering your products to your door.

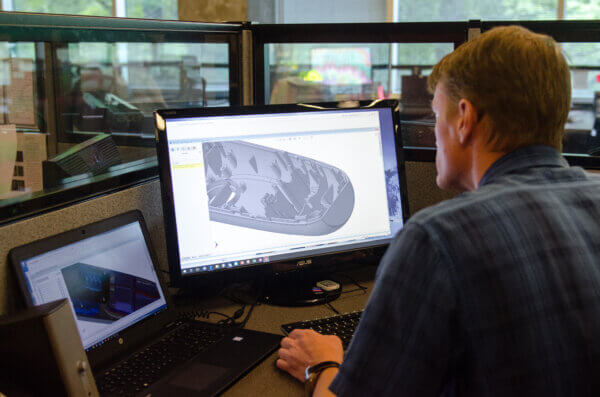

DESIGN

Our Asheville Design Center (ADC) is integrated with its sister team in Atlanta to guide customers through the processes required to transition your product from concept to mass production as well as provide support for the development of products, custom components, jigs, and test fixtures to drive efficiencies in manufacturing. Learn more about our Design Center here.

ENGINEER

Our U.S.-based Engineering team works closely with you to make sure your goals are front and center. Through careful listening and experience, we translate your expectations into clear specifications to execute the manufacturing process to your quality standards. Our priority is delivering design options that make your product more manufacturing-friendly while maintaining the functionality you need. Our team of engineers comes from diverse industries, creating innovative solutions during the design phase and throughout the entire manufacturing process. By allowing our engineering team to review your product during the design stage, we can help make recommendations on technologies that will provide a competitive advantage, or solve a problem before going into production.

We use Computational Fluid Dynamics (CFD) analysis software to demonstrate how air/water-moving systems respond to a variety of internal or external influences including increased or decreased flow, pressure, or temperature. Finite Element Analysis (FEA) software is used to test and simulate product behavior before production. Our design engineering team evaluates these variables during simulation and reviews the impact of changes to existing designs. Using CFD or FEA gives you a clear picture of the way your design will perform without having to create multiple prototypes and physical testing. The result? CFD and FEA allow for a quicker time to market while helping to create a better-performing product at the lowest cost.

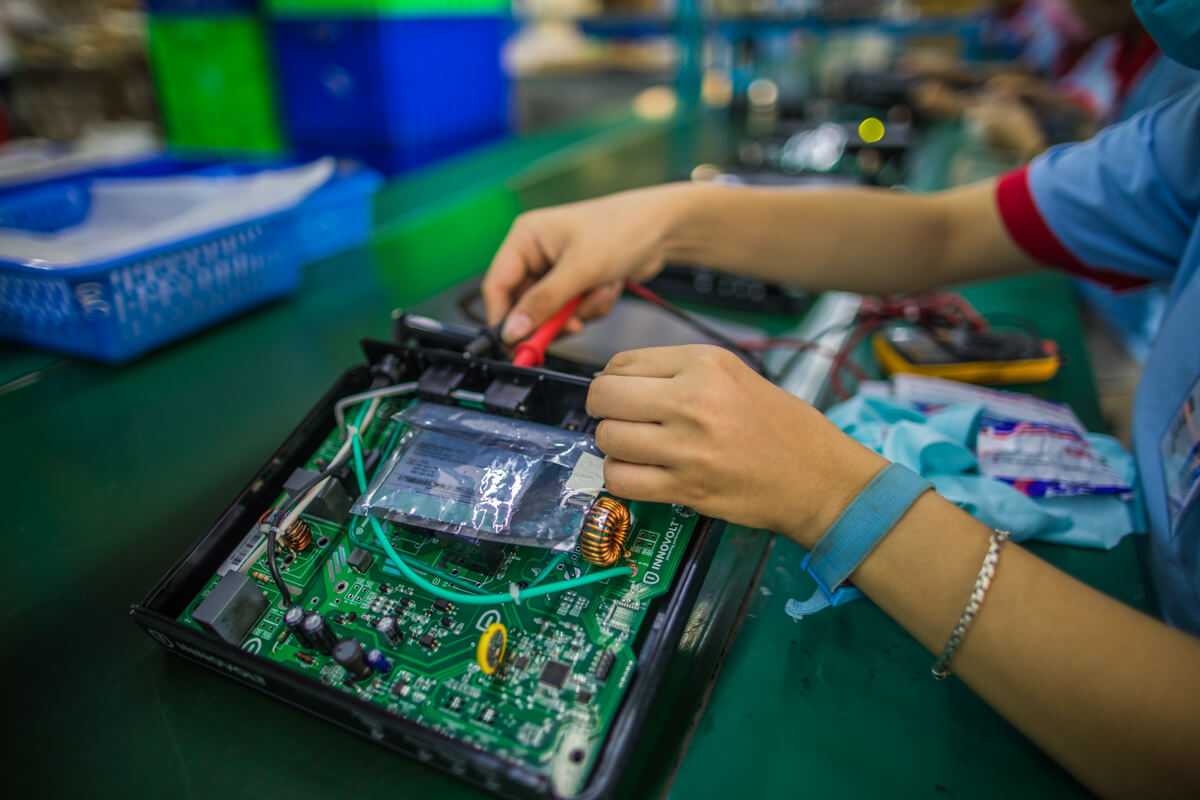

BUILD

At our core, East West is a global engineering and manufacturing services company focused on the realization of products, from design to distribution. Our manufacturing specialties include PCBAs, electrical assemblies, and sub-assemblies, high-precision die casting, CNC machining, wire and cable assemblies, metal stamping, plastic injection molding, in-house tooling, and assembly/testing capabilities.

Learn more about our core capabilities:

DISTRIBUTE

From loading containers to customs clearance, full logistics management to paperwork, and administrative functions, we handle every detail so you don’t have to. If you ever have a question about the status of your shipment, our Atlanta-based customer support team is only a phone call away. Our customer service and logistics teams work closely to ensure your product is delivered to your door on schedule.

SCALE

From initial concept to full-scale production, our experienced team of engineers and technicians provide services that meet your exact needs. We offer a wide range of prototyping, manufacturing, and testing services, allowing you to bring your product to market faster and at a lower cost.

Learn more about our Rapid Prototype Manufacturing Services.

MANAGE

Our US-based Engineering Services NPI team is comprised of experienced material science, mechanical and electrical engineers who work hand in hand with customer product development teams to ensure design and engineering intent is preserved throughout the NPI process.

Our relationships with key stakeholders and first-hand knowledge of East West’s overseas capabilities and best practices ensure on-time, in-full delivery of new products into production.

How does this benefit you?

U.S.-Based Engineering and Customer Support

Our Atlanta-based engineering and customer support teams are quick to respond to any inquiry and are only a phone call away if you have questions about your order. The commercial and technical aptitude of our engineers and field sales team allows us to expedite your requests and get your answers, faster.

Diversified Supply Chain with Competitive Pricing

Easily manage one single source with access to a global network and a wide range of manufacturing capabilities. Reap the benefits of working directly with a U.S.-based company offering offshore prices.

World-Class Quality Control

East West is committed to Total Quality Management. With our highly trained and qualified staff of both in-house and third-party inspectors, such as UL, you can be confident your products are produced to meet your specifications in our factories. Our PPM defect levels are significantly lower, compared to industry averages.

Read about the problems we solve for our customers.