Our Printed Electronics and HMI Technology capabilities include wearable devices, membrane switches, In-Mold Electronics (IME), projected capacitive switches, silicone rubber keypads, graphic overlays, touchscreens, ITO replacement Films, and functional screen printing for E-Textiles/Smart Clothing.

Screen-Printed Electrodes & Biosensors

With deep Printed Electronics industry knowledge and a full complement of state-of-the-art equipment, our team is experienced with even the most challenging projects including high-tech, high-performance screen-printed electrodes (SPEs) and biosensors.

Electrodes and biosensors are complex and sensitive, requiring extensive quality systems and statistical process controls to ensure the highest levels of quality are achieved 100% of the time in production. We have designed the latest medical and diagnostic electrochemical biosensor products, and our precision printing, processing, and product development expertise has helped customers in all fields receive the best quality electrodes and biosensors in the industry.

We offer:

- Functional conductive ink and fine-line printing

- Engineering

- Design assistance

- Rapid or production-quality prototyping

- Embossing

- Thru-hole printing

- Hydro-gels

- Medical grade foams

- Silver chloride ink

Our materials are of the highest quality and include a broad array of inks, including radiolucent conductive, carbon, zinc, and dielectric. Available state-of-the-art precision screen printing methods include automated and semi-automated sheet feeds, roll-to-roll printing, with die cutting, and gel dispensing.

Wearable Technology

As wearable electronic devices continue to be more and more prevalent, it becomes an ever-greater challenge for companies that manufacture them to keep their competitive edge. It is vitally important for manufacturers that each device is effective, cost-efficient, and reflects the highest quality. Our circuits and assemblies are used for the most challenging applications and in the most demanding industries on the market. To meet the needs of this growing segment, we offer the broadest range of wearable circuit technology available. This includes screen-printed circuits, electrodes, and sensors, all available with fast and cost-effective assembly operations.

One of the fastest-growing applications of wearable technology is in the medical field. This includes patient-worn patches, all requiring a high degree of engineering expertise. We employ the most advanced adhesives, functional printing methods, ink selections, fabrication and assembly methods, hydro-gels, and packaging options to optimize these products' performance and speed to market.

Industries Served

Medical

Patient Monitoring, Screen Printed Biosensors

Industrial Controls

Fuel dispensing, Security

& Fire Safety

Appliance

Consumer & Commercial

Other

E-Textiles, Military, Aero & Consumer

Transparent Printed Electronic Applications

One of the most widely used electronic applications today is capacitive touchscreen technology. Touch screens are ubiquitous in personal and professional devices. Our team of experts provides design and assembly services to fabricate the highest quality touch films and system integration of touch screens available in the industry.

A complete array of touch film and assembly options are available. These include:

- Multi-point contact touch films

- Discrete contact point touch films

- Display integration

- Optically laminated windows

- In-mold decorating

- Plastic bezels

- Single or double-sided film

- Film-on-glass and film-on-film

We provide our customers with a diverse array of user-specific features. Some of these include various transmission and haze percentages, polyester or polycarbonate circuit films, and graphic overlays with hard coating and surface texturing.

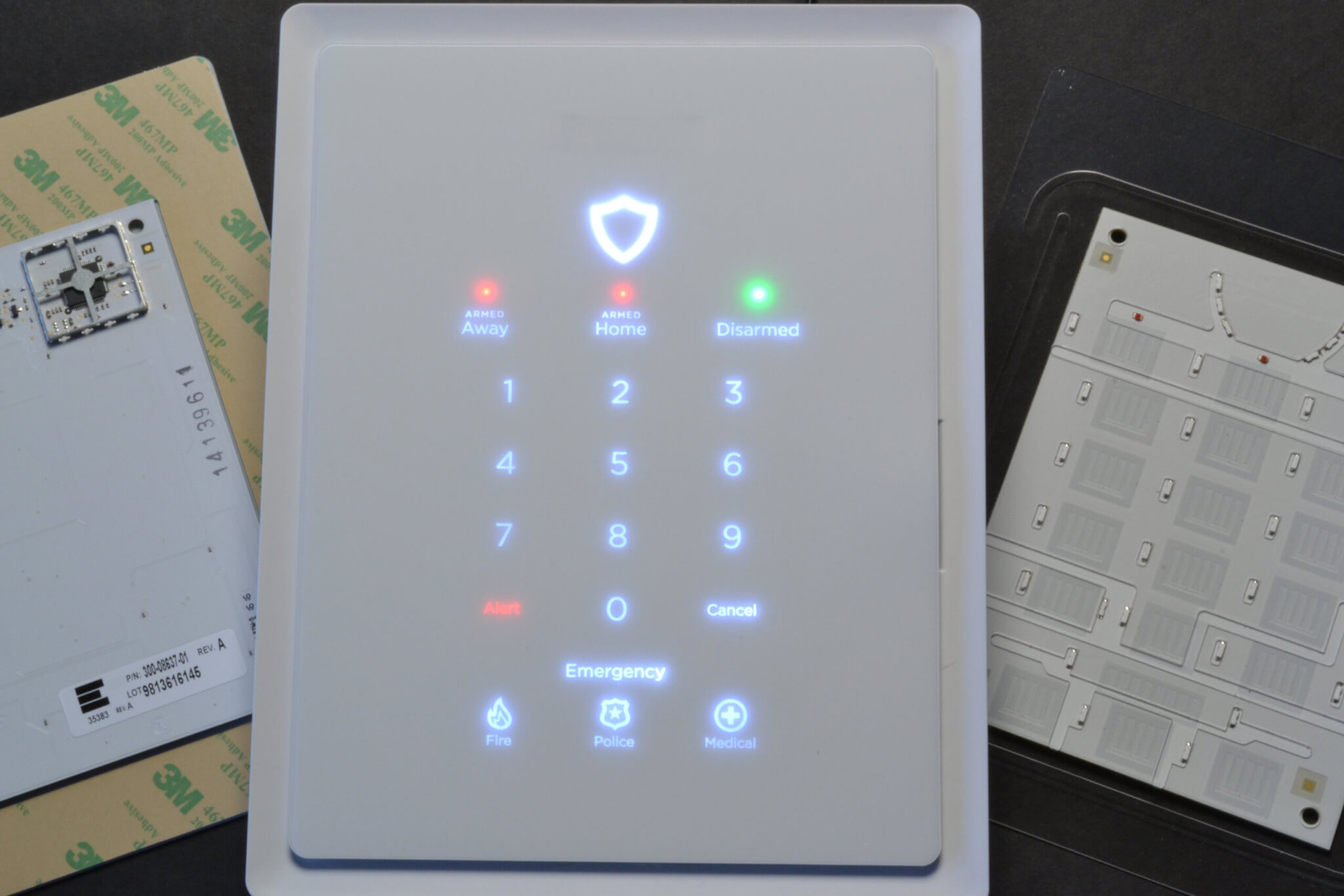

Membrane Switches

We have been producing custom keyboard assemblies with membrane switch technology for decades. Our engineering expertise, experience, and wide breadth of capabilities lead to the highest quality membrane switches and electronic front panel assemblies available on the market. With two 30,000 sq. ft. manufacturing facilities that are ISO 9011 and ISO 13485 certified, and fully ITAR compliant, we can perform all operations in-house to the most stringent industrial standards.

Some of our membrane switch design options include:

- CAD/3D modeling

- Dead front graphics

- Display integration

- Metal backers

- Interchangeable graphics

- Optically laminated windows

- Plastic bezels

- Tinted Windows

- Touch screen system integration

- Graphic embossing

- In-mold decorating

- Silicone rubber keypads and overlays

- Discreet LED and custom light guide backlighting

- Conductive seals

Screen printing and assembly services are also available. We employ automated and semi-automated sheet-fed and roll-to-roll printing, as well as automated pick and place, hand insertion, hand soldering, roll, and hand lamination assembly methods. Our low-cost labor facility in Mexico supports OEMs in a broad array of industries while ensuring the most competitive prices on the market.