East West Manufacturing offers Surface Mount Technology (SMT) capabilities through our Electronics Manufacturing Services (EMS) division located throughout the world, including our five-building complex in Vietnam, Wisconsin, Mexico, Quebec, and Costa Rica. East West has scalable, state-of-the-art, lead-free facilities to manufacture printed circuit boards (PCBs) and complete box-build assemblies. With our global ISO 9001:2015, ISO13485:2016, and ISO 14001 certifications, our customers can be assured that East West can meet quality requirements continually.

East West Manufacturing offers Surface Mount Technology (SMT) capabilities through our Electronics Manufacturing Services (EMS) division located throughout the world, including our five-building complex in Vietnam, Wisconsin, Mexico, Quebec, and Costa Rica. East West has scalable, state-of-the-art, lead-free facilities to manufacture printed circuit boards (PCBs) and complete box-build assemblies. With our global ISO 9001:2015, ISO13485:2016, and ISO 14001 certifications, our customers can be assured that East West can meet quality requirements continually.

Our experienced engineering team provides superior solutions for new product development projects including design for manufacturability and design for testability (DFM/DFT). Our lean culture enables continuous improvement efforts ensuring we provide our customers with the lowest “total cost” solution.

Watch a quick video about our EMS capabilities in Vietnam below:

We provide world-class electronic manufacturing services currently used in:

- Energy Efficient EC (Electronically Commutated) Motors

- Medical and Beauty Devices

- Industrial Power Protection

- Fan and Blower Assemblies

- Consumer Electronics – IoT Wearables

- Security Systems

- Pump Controllers

- Refrigeration IoT Controls

- Power Control Assemblies

- Network infrastructure

- Industrial controls

- Automatic Meter Reading

- Defense/Homeland Security

- Electrical Power Generation

- LED Lighting Solutions

- Safety Systems

- Radio Frequency Systems

- Vehicle Systems

- Laboratory Instrumentation

Our unique global footprint allows our customers to stay with one trusted manufacturing partner throughout the growth of their company and product demand. Whether you're just starting and need a few EMS prototypes or need high-volume, low-mix PCB Assemblies, we can help your project come to life with the support of our Vietnam facility's in-house tooling shop, injection molding machines, pad printing, sonic welding, test laboratory, and full assembly operations.

All electronics assemblies, sub-assemblies, and box-builds are made and inspected to IPC-A-610 standards. Agency approvals include UL, CSA, CE, and RoHS.

Modern EMS Facilities

Our SMT lines are equipped with new current generation machines including:

- Pick & Place Machines - Placement rate of 55,000+ components per hour with an accuracy of +/- 50μm @ 3 sigma

- Screen Printer - Fully automatic vision alignment with a rapid changeover of fewer than 5 minutes

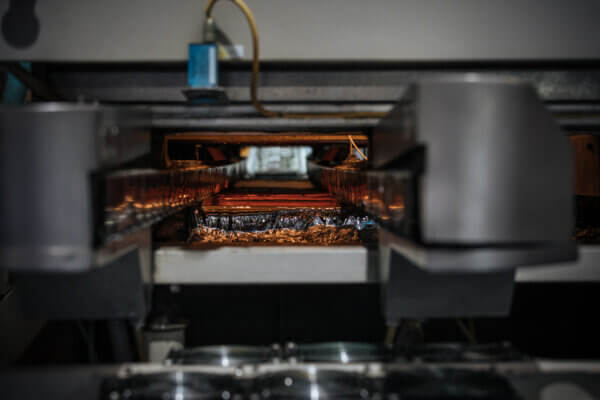

- Reflow Oven - Accommodates a wide range of boards and double-sided reflow capable

- Wave Solder Machine - Ultrasonic spray fluxer for precise control of flux application and dual wave solder fountains for broader capabilities

- Automatic Conformal Coating - 4-axis protective coating spray machine with IR oven cure

- In-Circuit Testing (ICT) - Automated testing of electrical characteristics on populated circuit boards

- Functional Circuit Testing (FCT) - Custom fixtures developed with the assistance of our customer service engineering team

Scalable Manufacturing

East West offers the flexibility to accommodate New Product Introduction (NPI), Complete Box Builds (including 4-color retail packaging) and full production runs. Our modular approach with plug-in scalability allows our engineers to quickly adapt to customer demands.

Board Handling Range

We can handle the smallest components available today on boards up to board size 15.75”x18” as well as single, double-sided and multi-layer boards. East West can accommodate board thickness between 0.015” and 0.165”.

What Else Can an EMS Manufacturer Do for You?

East West provides additional processes such as injection-molded plastic housing, laser cutting, custom magnetics, cable and wire assembly, or vacuum forming, to complete your electronics project’s needs.

Injection Molding Capabilities

We have access to injection molding machines up to 800 tons to meet all your molding needs. Injection molding tooling is offered with prototype molds available. We offer tooling warranty, providing full maintenance and replacement at end of life.

In-House Tooling

East West’s very own tool shop (Vietnam) provides our customers in-house tool manufacturing expertise, reduced tooling cost and increased speed to market for production. From simple single cavity to complex multiple cavity, slides, gates and injector pin designed molds, we have the technical skills and equipment to manufacture precision molds for your unique project.

A Range of Complementary Capabilities

Providing more than just Electronic Manufacturing Services, East West offers engineering support and design services, in-house tooling (Vietnam), plastic injection molding (Vietnam), electrical assemblies and sub-assemblies, SMT, CNC machining, high-precision die casting, EC Motors, cable and wire harness assembly, and testing capabilities.

Competitive Pricing with U.S.-Based Engineering and Customer Support.

East West is committed to Total Quality Management. With our highly trained and qualified staff of both in-house and third-party inspectors, including UL, you can be confident your products are produced to meet your specifications in our factories. Our PPM defect levels are significantly lower, compared to industry averages. We not only ensure competitive pricing, but also further maximize your competitiveness by delivering the highest quality possible.

Our Atlanta-based engineering and customer support teams are quick to respond to any inquiry and are only a phone call away if you have questions about your order. The commercial and technical aptitude of our engineers and field sales team allows us to expedite your requests and get your answers, faster.