The HMI (Human Machine Interface) division of East West, located outside of Boston in North Andover, MA, offers capabilities for a wide range of industries utilizing both HMI technology and printed electronics. The facility is ISO 9001, ISO 13485 certified, and fully ITAR compliant, making us ideal for those in the medical or defense sectors.

Screen-Printed Electrodes & Biosensors

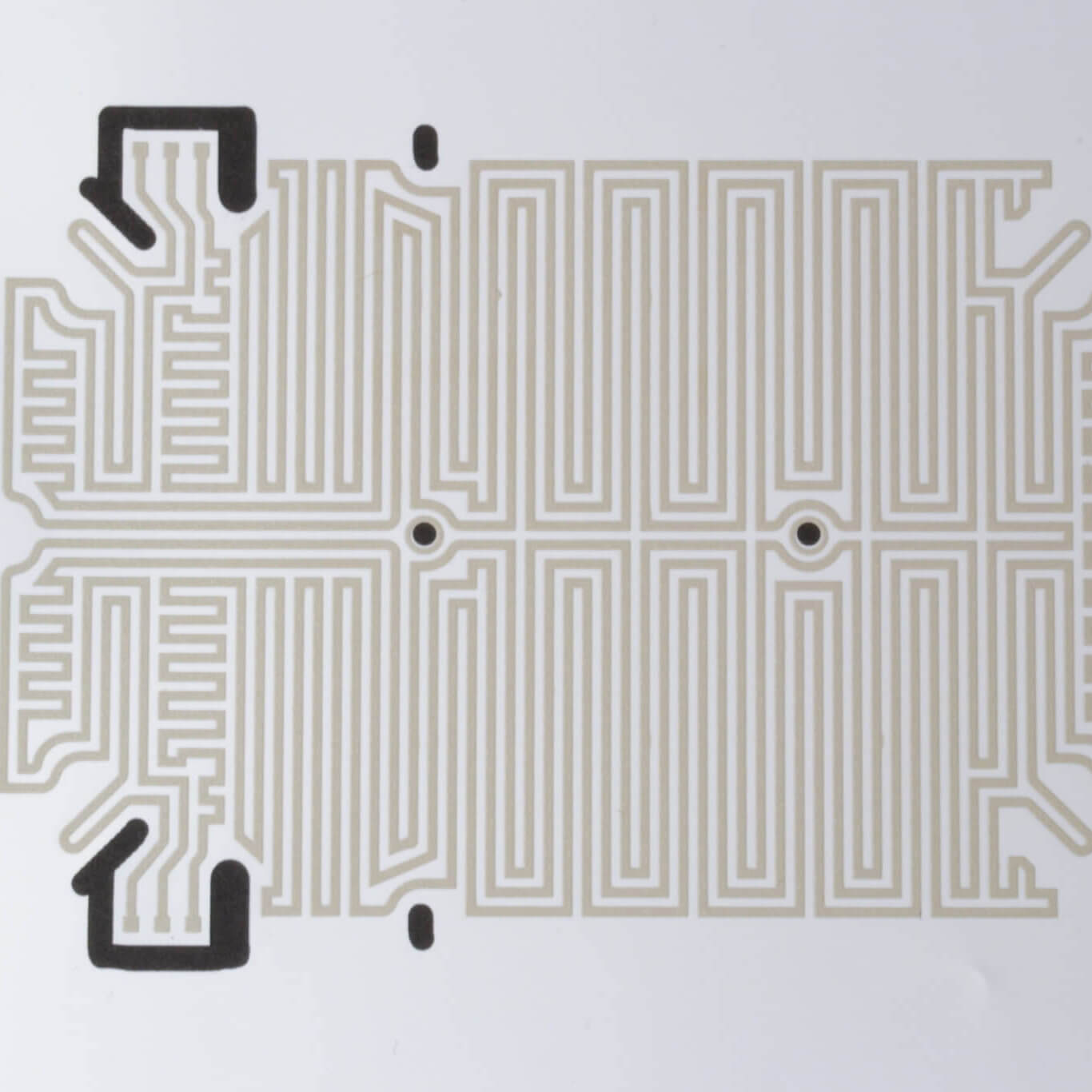

With deep Printed Electronics industry knowledge and a full complement of state-of-the-art equipment, our team is experienced with even the most challenging projects including high-tech, high-performance screen-printed electrodes (SPEs) and biosensors.

We have designed the latest medical and diagnostic electrochemical biosensor products, and our precision printing, processing, and product development expertise results in the best quality electrodes and biosensors in the industry.

We provide a broad array of inks, including radiolucent conduction, carbon, zinc, and dielectric.

Industries Served

Medical

Patient Monitoring, Screen Printed Biosensors

Industrial Controls

Fuel dispensing, Security

& Fire Safety

Appliance

Consumer & Commercial

Other

E-Textiles, Military, Aero & Consumer

Wearable Technology

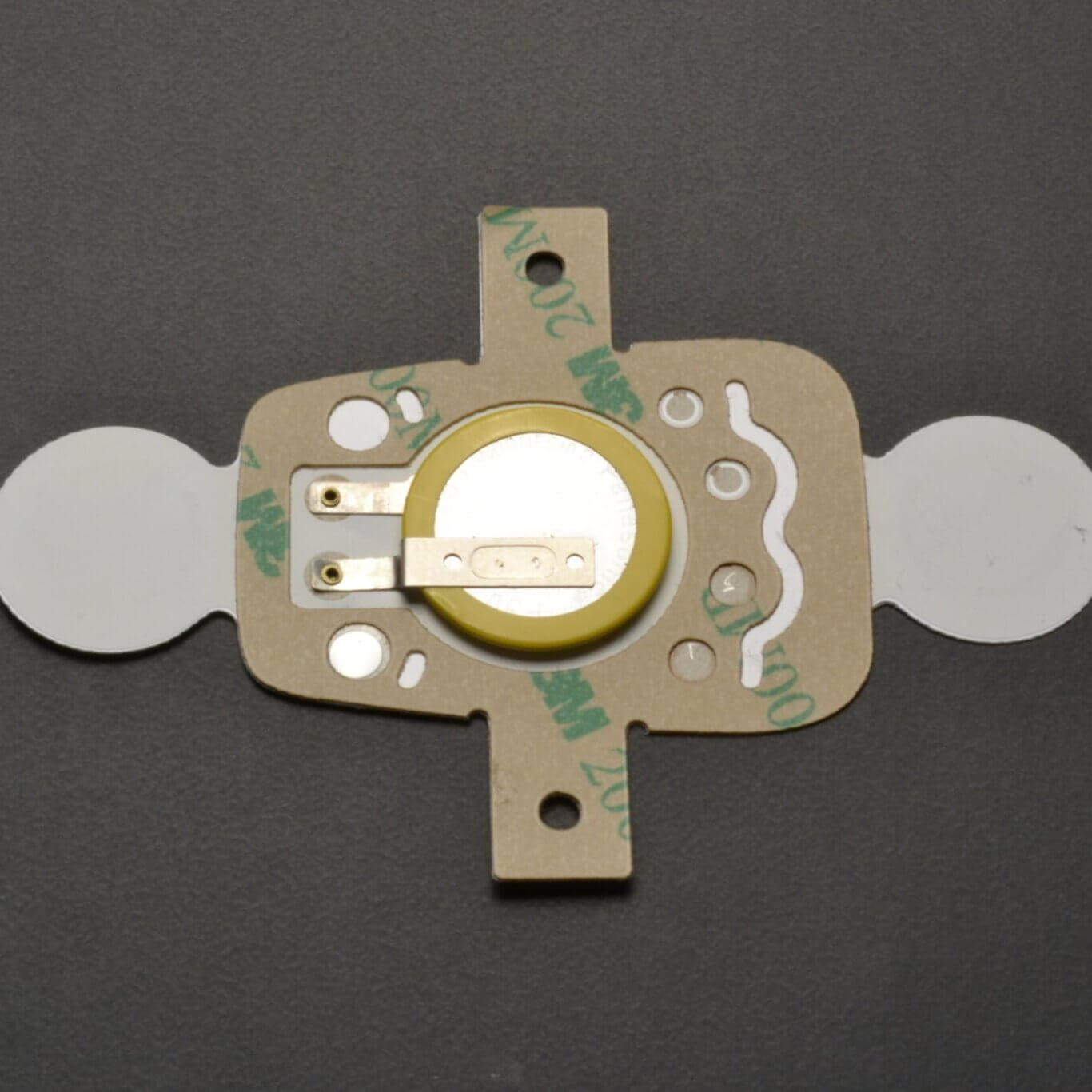

Our circuits and assemblies are used for the most challenging applications and in the most demanding industries on the market. To meet the needs of this growing segment, we offer the broadest range of wearable circuit technology available. This includes screen-printed circuits, electrodes, and sensors.

One of the fastest-growing applications of wearable technology is in the medical field. This includes patient-worn patches, all requiring a high degree of engineering expertise. We employ the most advanced adhesives, functional printing methods, ink selections, fabrication and assembly methods, hydro-gels, and packaging options to optimize these products’ performance and speed to market.

Transparent Printed Electronic Applications

One of the most widely used electronic applications today is capacitive touchscreen technology. Touch screens are ubiquitous in personal and professional devices. Our team of experts provides design and assembly services to fabricate the highest quality touch films and system integration of touch screens available in the industry. A complete array of touch film and assembly options are available.

We provide our customers with a diverse array of user-specific features. Some of these include various transmission and haze percentages, polyester or polycarbonate circuit films, and graphic overlays with hard coating and surface texturing.

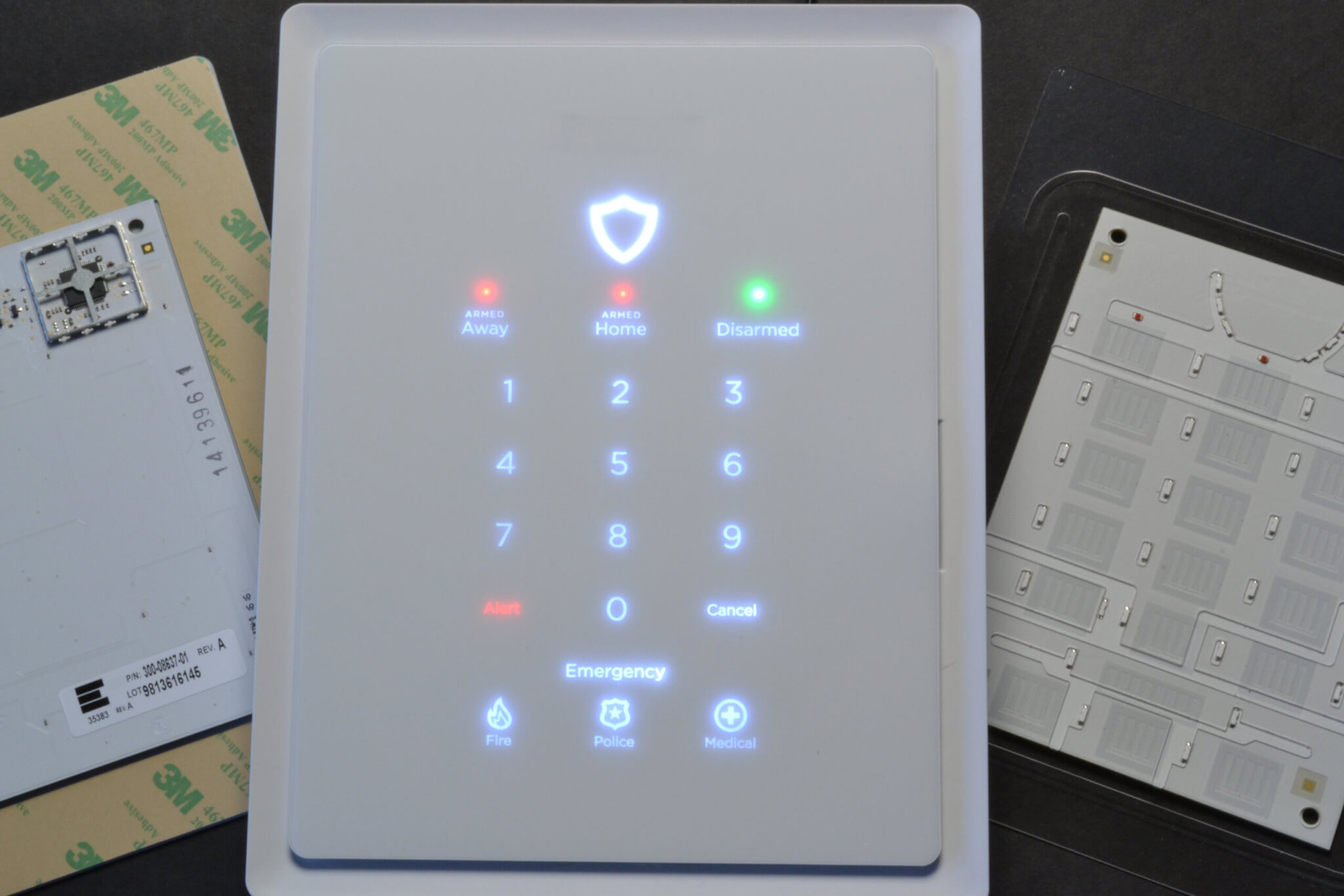

Membrane Switches

Our HMI division has produced custom keyboard assemblies with membrane switch technology for decades. The engineering expertise, experience, and wide breadth of capabilities give customers the highest-quality membrane switches and electronic front panel assemblies available on the market.

Screen printing and assembly services are also available. We employ automated and semi-automated sheet-fed and roll-to-roll printing, as well as automated pick and place, hand insertion, hand soldering, roll, and hand lamination assembly methods. Our low-cost labor facility in Mexico supports OEMs in a broad array of industries while ensuring the most competitive prices on the market.

Printed Electronics and HMI Capabilities:

- Wearable Devices

- Membrane Switches

- In-Mold Electronics (IME)

- Silicone Rubber Keypads

- Projected Capacitive Switches

- Touchscreens

- Graphic Overlays

- ITO Replacement Films

- Functional Screen Printing for E-Textiles/Smart Clothing