People in the Carolinas are Resilient. Between the long, hot summers and ups and downs of the Panthers, Hurricanes, Tar Heels, Blue Devils, and Wolfpack you must be!

But what about your supply chain? The reality is our world is different today. Manufacturing used to follow the “or” theory, meaning products had to be made here “or” over there and many companies chose “over there” because it was cheaper.

If our industry has learned nothing else over the past few years, it has experienced the importance of crafting a resilient supply chain by implementing the “and” theory. You have made it crystal clear that products must be made here “and” over there.

Diversity in the supply chain is no longer an option – it the rule.

It’s time to reshore America, and that starts right here in the Carolinas.

East West North Carolina's Core Capabilities

Specializing in low volume, high mix production for high complexity PCBAs and electromechanical assemblies, our Raleigh and Charlotte, North Carolina facilities allow companies to begin with lower volumes then access streamlined integration to a global supply base and offshore operations once it is time to scale production.

Our Charlotte facility is ISO 9001:2015, ISO 13484:2016, ISO 14001, ISO 80079-34, and an EPA Certified Green electronics manufacturing services provider. Our Raleigh facility follows IPC-A-610 Class II and IPC/WHMA-A-620 Class II standards.

New Product Introduction

Our Center of Excellence makes NPI as convenient as possible through our vertically integrated model. The comprehensive approach to NPI, along with our quick-turn capabilities, allows us to help you navigate from prototype to pre-production, avoiding potential pitfalls that could result in increased time to market or cost. We also have the ability to fulfill your need for small production batches.

Box Builds

Box build capabilities in North Carolina allow us to provide you with everything from PCBA to cable and wire interconnects, final box build, and packaging. We also offer the flexibility to price and source your own parts, if needed, leaving final assembly to us. Our services include sublevel product assembly, system-level assembly, software loading, and product configuration, testing, packaging, and labeling.

PCB Assembly Capabilities

PCB Assembly services focus on advanced electronics requiring low volume, high mix production for high complexity printed circuit board, and electromechanical assemblies. We are compatible for PCB assembly requiring multi-layer, double-sided, BGA, and high component count.

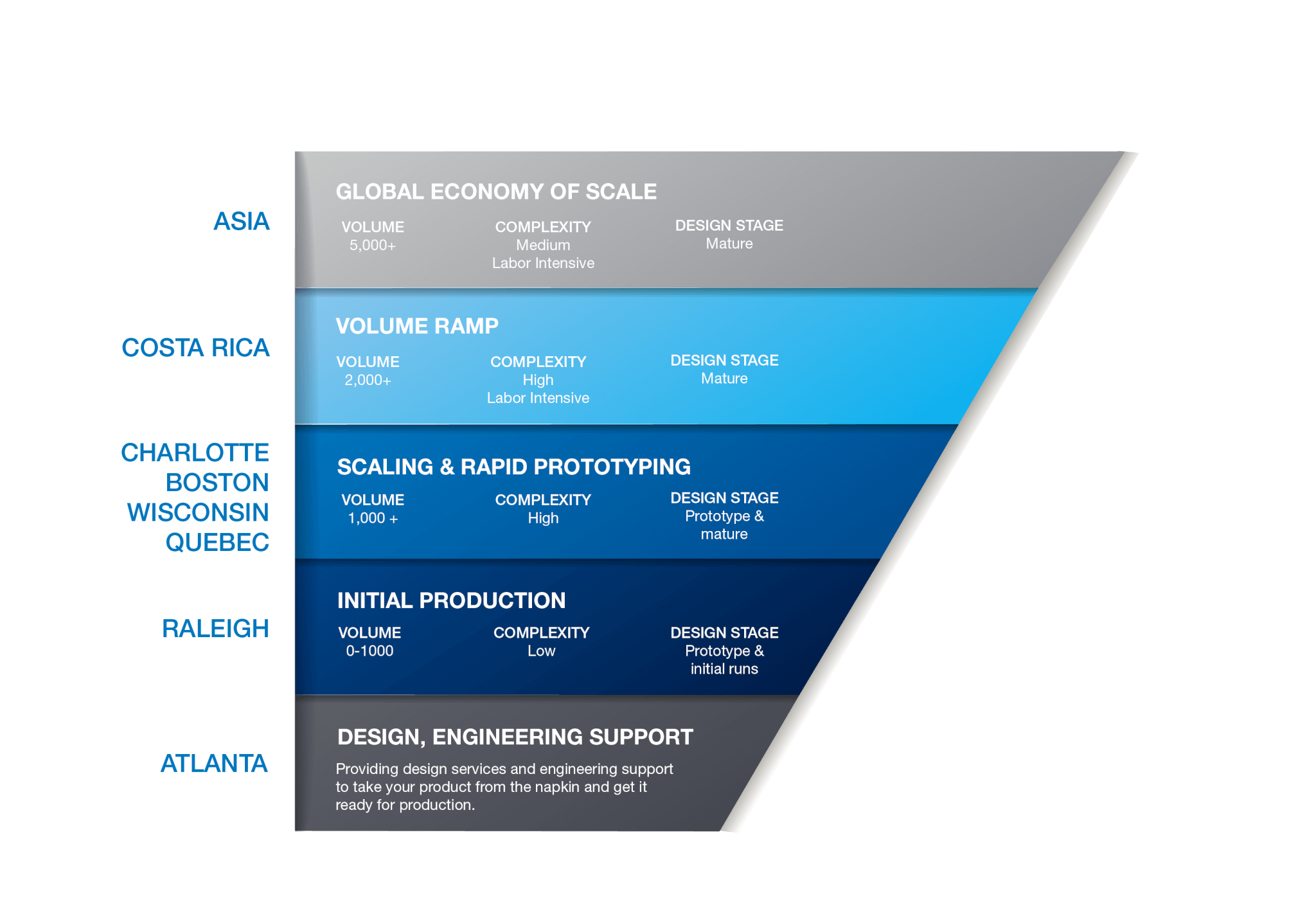

Local, Nearshore, and Offshore

East West’s Charlotte and Raleigh facilities give you access to world-class electronic manufacturing services and box build assembly in your back yard, AND we can balance higher volume in places like Costa Rica and Vietnam. You can benefit from here and there to create a bullet-proof supply chain so your customers can always depend on you!

Walk Through Our Factory

A Product Realization Company

We are not only industry experts at managing projects from design to delivery but are also committed to giving our customers the best possible experience by working with dedicated U.S.-based engineering and customer support teams and producing products to world-class standards in an easy, efficient manner.

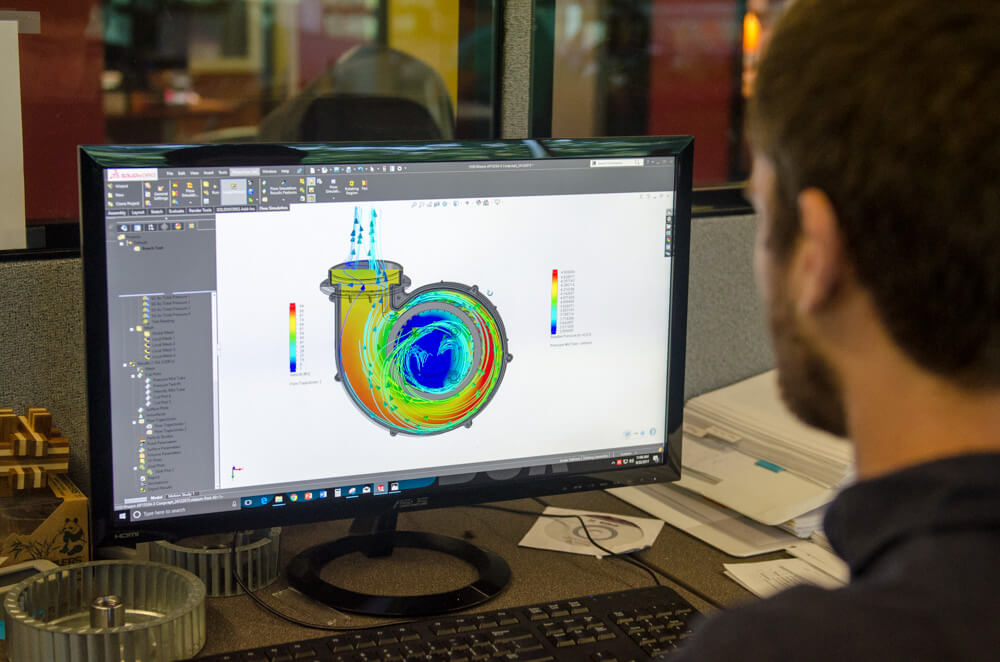

Design Services

Our talented team has experience in all aspects of mechanical and mechanism design including FEA and CFD simulations.

Manufacturing

East West offers a complete supply chain solution with manufacturing operations in 14 locations in 9 global destinations.

Distribution

We are your end-to-end logistics solution. We offer warehousing, distribution, and cross-docking services for our customers.