Our EMS prototyping process mirrors our production schedule. Once your quote package is received, we’ll begin working on returning an accurate quote as soon as possible, depending upon complexity of the project.

There are always questions during this stage, and your dedicated program manager will work with you through the entire process. After the quotation is accepted, we’ll take your purchase order, create a Bill of Material (BOM) and load it into our ERP system to make sure our lead times meet your production schedule.

Your QA procedures and testing requirements are important to us and critical to your functionality. We welcome your engineers into the facility to be on the line during manufacturing. We want to get it right the first time and on time, so expect our team to work with you to ensure validation requirements are being met.

By leveraging relationships within our supply chain network, we can help with design, FCC or other 3rd part certification requirements.

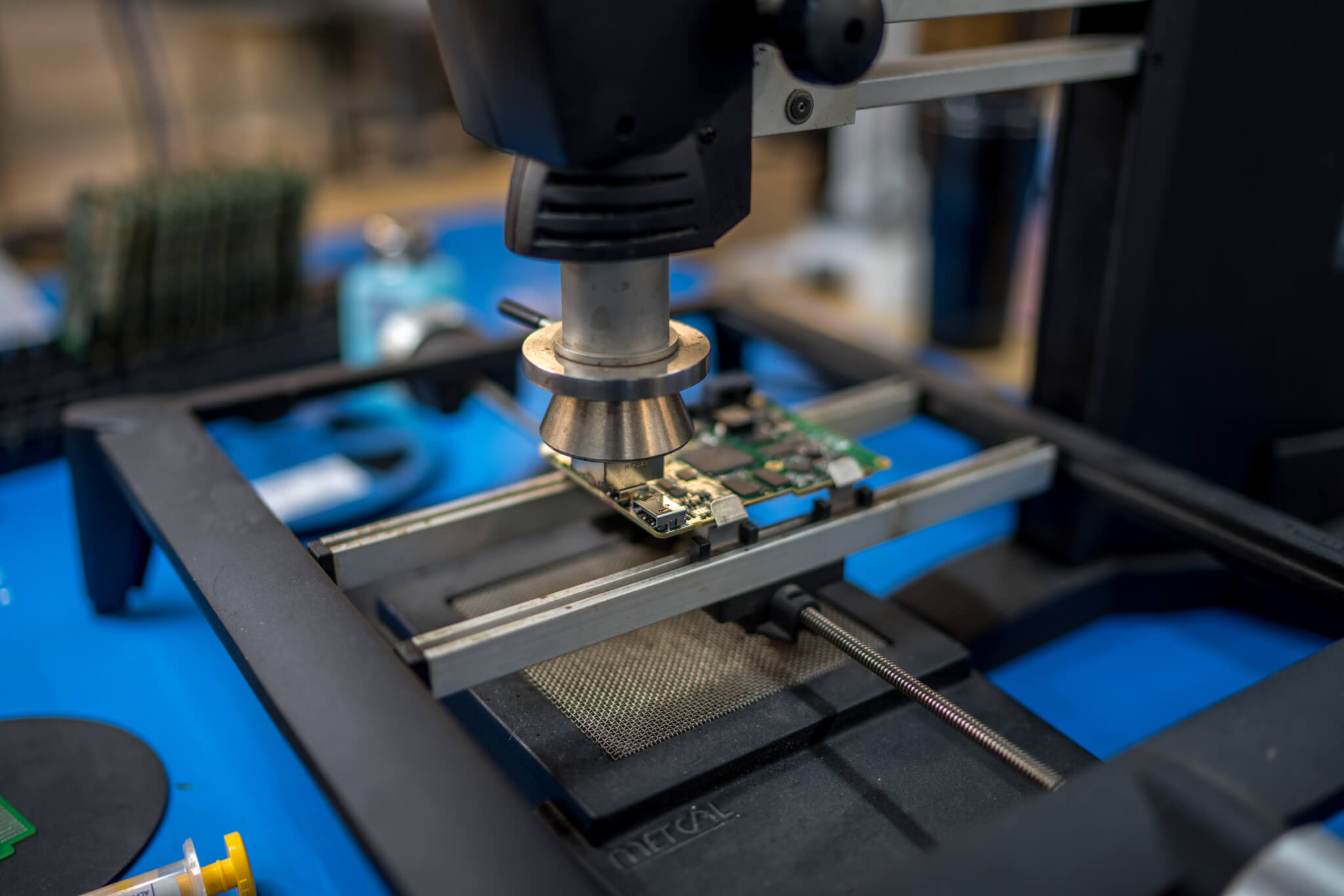

If you need one PCBA or thousands, a simple LED or an 18” x 18” board with 6,000 components, our EMS prototyping capabilities will deliver the results you need.